Wenzel's theory reveals that the relationship between surface roughness and coating adhesion is not straightforward. Contrary to common belief, increasing the depth of surface roughness on a blast-cleaned surface doesn't universally enhance coating adhesion. This phenomenon is particularly evident with high-viscosity liquids or low-temperature powder coatings. These coatings often struggle to penetrate and displace air trapped within the valleys of the surface profile. This air entrapment creates a barrier that reduces the effective contact area between the coating and the substrate. The physics behind this challenge lie in the surface tension and viscosity of the coating material. High-viscosity liquids have a higher resistance to flow, making it difficult for them to infiltrate microscopic surface features. Moreover, low-temperature powder coatings may not achieve sufficient flow to effectively wet and bond with the substrate, further complicating adhesion.

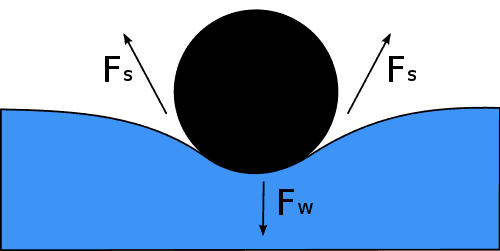

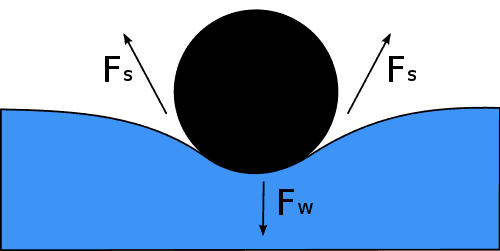

The coating industry faces a significant challenge in accurately measuring and characterizing surface profiles to predict adhesion. Traditional metrics like Ra (average roughness), Ry, Rz (peak-to-valley height), or peak count (peaks per unit length) do not provide a comprehensive understanding of surface topography in three dimensions. These parameters fail to account for factors such as surface energy and contact angle, which are crucial for predicting how well a coating will adhere. Surface energy is influenced by the chemical composition and structure of the substrate, affecting its wetting properties. Surface energy is nothing more than the attractive or adhesive forces that occur between the molecules of the coating and those of the substrate. Therefore, the more compatible these types of molecules are, the higher the surface energy and hence the greater the adhesion. Coatings with higher surface energies tend to spread more evenly and adhere better to substrates. Understanding these chemical interactions is essential for designing effective surface preparation methods that optimize surface energy and enhance coating adhesion.

The distinction between mechanical adhesion in tension and shear is pivotal in selecting appropriate adhesion test methods. Tensile stresses, which pull apart the coating from the substrate, are less common in practical applications compared to shear stresses, where forces act parallel to the substrate interface. Shear stresses are particularly significant in coated systems subjected to environmental and operational stresses. The physics underlying these stresses involve the distribution of forces across the interface, influenced by the mechanical properties of the substrate and coating. Ensuring that adhesion tests simulate realistic stress conditions is critical for accurately assessing the performance and longevity of coatings in real-world applications.

Current industry standards often emphasize tensile (pull-off) strength as the primary measure of adhesion. However, this approach may oversimplify the complex interplay of forces at the coating-substrate interface. Coating specifications should account for the dominant stress conditions experienced by the structure in service, which may vary based on factors such as temperature fluctuations, mechanical loading, and exposure to corrosive environments. This understanding drives the need for more nuanced adhesion testing protocols that reflect the specific stress conditions relevant to each application.

Wenzel's theory underscores the need for tailored surface preparation to optimize adhesion for different coating types and substrates. Factors such as viscosity, particle size distribution, coating flow characteristics, substrate chemistry, and surface temperature play critical roles in achieving optimal wetting and adhesion. The physical and chemical properties of the coating material interact with the surface profile to determine the extent of surface coverage and bonding. Achieving an ideal balance between surface roughness and surface energy is key to maximizing adhesion performance across diverse coating applications.

Recent advancements in surface measurement technologies, such as 3-D replica tape systems, represent promising steps toward more accurate and comprehensive surface profiling. These technologies provide detailed insights into the three-dimensional topography of surfaces, including parameters like peak count/density and developed surface area (Sdr). However, further research is needed to establish clear correlations between these advanced measurements, coating performance under different environmental conditions, and long-term durability. Enhancing our understanding of these relationships will contribute to more informed decisions in coating selection, surface preparation, and performance evaluation.

In conclusion, while surface profile parameters are critical indicators of coating performance, their interpretation and application require a deeper understanding of the underlying physics and chemistry. Advances in measurement techniques and testing protocols are essential for refining industry standards and optimizing coating systems for enhanced durability and reliability in diverse operational environments