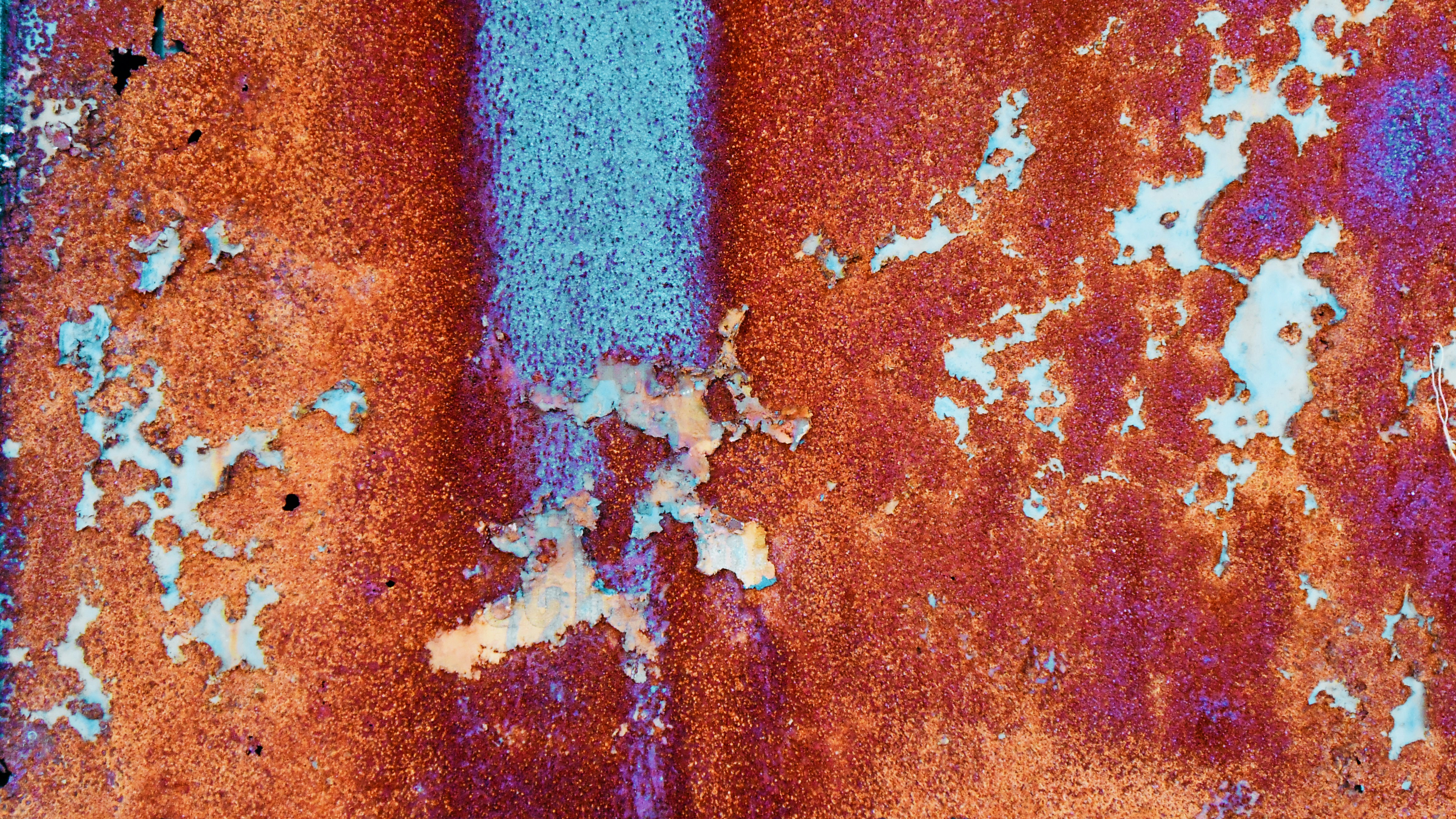

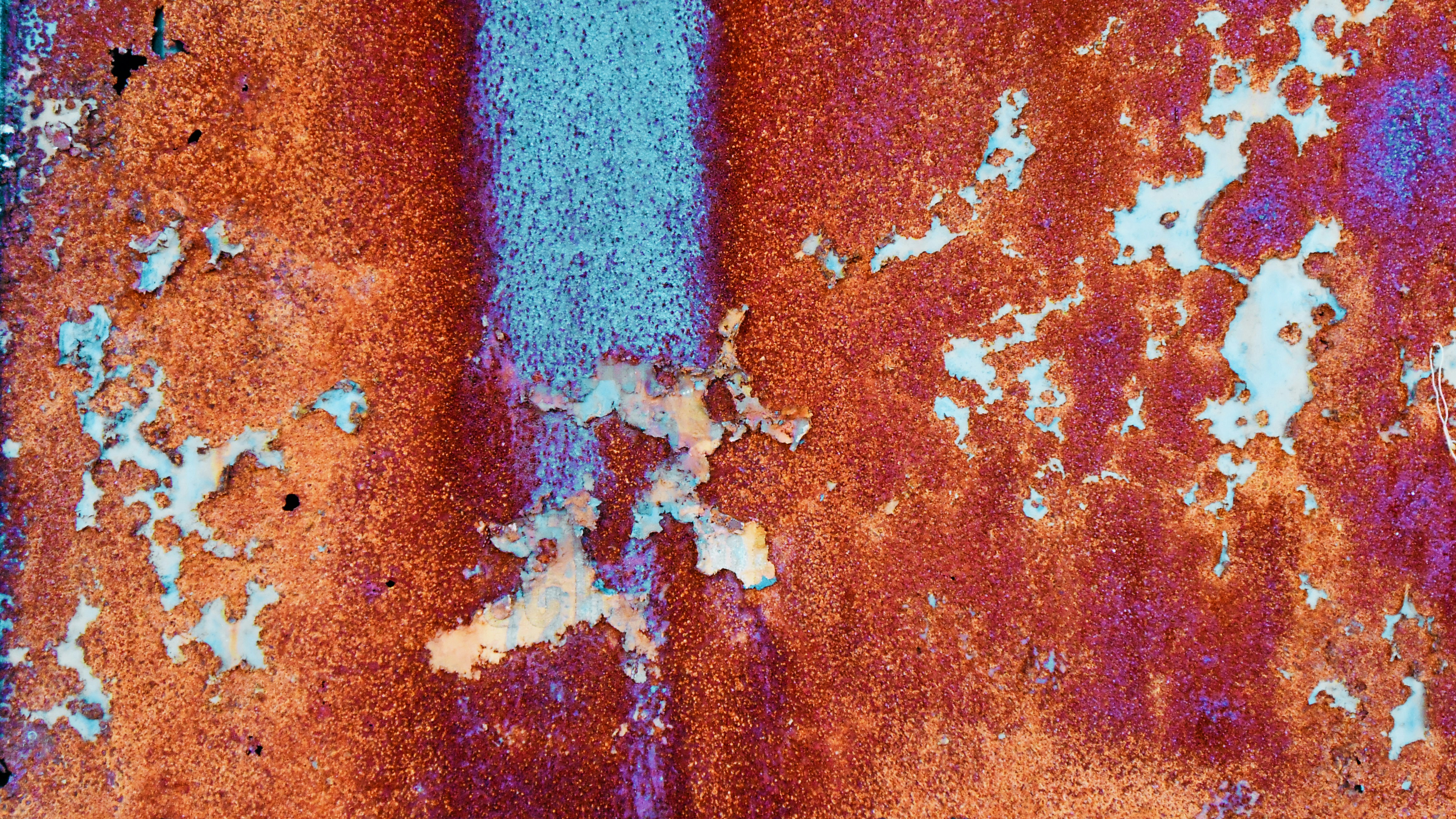

Corrosion is a pervasive and costly issue that can compromise the integrity and lifespan of metal structures. Coating paints play a vital role in mitigating corrosion by employing various protective mechanisms, including inhibition. Inhibition involves the use of corrosion inhibitors in coating paints to chemically interact with the metal surface and inhibit the electrochemical reactions that lead to corrosion. This article will delve into the inhibition mechanism and its significance in corrosion protection provided by coating paints.

Chemical Interaction

Corrosion inhibitors contained in coating paints form a chemical bond with the metal surface, creating a protective layer that acts as a barrier to corrosive agents. This interaction alters the electrochemical properties of the metal surface, reducing its reactivity and susceptibility to corrosion.

Passive Film Formation

Inhibition can lead to the formation of a passive film on the metal surface, which acts as a protective barrier against corrosion. This passive film enhances the resistance of the metal substrate to corrosion by isolating it from the corrosive environment and minimizing the electrochemical reactions that promote corrosion.

Anodic and Cathodic Inhibition

Corrosion inhibitors can inhibit both anodic and cathodic reactions involved in the corrosion process. Anodic inhibitors reduce the rate of metal oxidation, while cathodic inhibitors suppress the reduction reactions that consume the electrons generated during metal oxidation. By inhibiting both types of reactions, corrosion inhibitors effectively mitigate corrosion and extend the lifespan of the coated metal substrate.

Types of Corrosion Inhibitors

Various types of corrosion inhibitors, such as chromates, phosphates, molybdates, and organic compounds, are utilized in coating paints to provide inhibition. Each type of inhibitor offers unique corrosion protection properties and is suitable for different environmental conditions and metal substrates.

Advantages of Inhibition Mechanism

Improved corrosion resistance

Inhibition enhances the corrosion resistance of coating paints by reducing the rate of corrosion initiation and progression, thereby prolonging the lifespan of the coated metal substrate.

Versatility

Corrosion inhibitors can be incorporated into various types of coating paints, including epoxy, polyurethane, acrylic, and alkyd coatings, making them versatile and adaptable to different applications and environments.

Environmental compatibility

Many modern corrosion inhibitors used in coating paints are environmentally friendly and comply with regulatory standards for reduced toxicity and environmental impact, making them suitable for use in eco-friendly and sustainable coating systems.