Fluoropolymers coatings

In today's industrial landscape, the demand for coatings that can withstand the toughest conditions while maintaining optimal performance has never been higher. Among the numerous options available, fluoropolymer coatings stand out as beacons of innovation and reliability. With a plethora of desirable properties, they have become indispensable in various industries, from aerospace to medical applications.

At the heart of fluoropolymer coatings lies a sophisticated molecular architecture, combining the robustness of the carbon skeleton with the resilience of fluorine bonds. But what sets them apart? These coatings exhibit a notable variety of characteristics:

Weather Resistance and Corrosion Protection: Fluoropolymer coatings offer a solid defense against corrosion and degradation, ensuring longevity even in the harshest environments.

Chemical Inertness: Fluoropolymers remain steadfast, maintaining their integrity in the face of chemical adversity.

Flame Retardancy: In the realm of safety, fluoropolymer coatings take center stage, offering inherently flame-retardant properties that enhance protection against fire hazards.

Nonstick and Low Friction: These coatings reduce friction and adhesion, promoting a finish that stains less and reducing maintenance costs.

High Dielectric Constant: Fluoropolymers exhibit a high dielectric constant, ensuring reliable insulation even under demanding conditions.

Chemistry

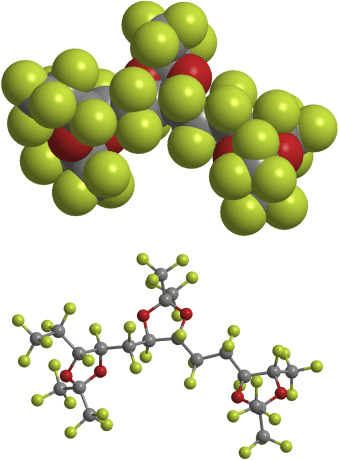

The secret of the exceptional properties of fluoropolymers lies in their atomic structure. Carbon and fluorine atoms, bound by covalent bonds, form a formidable shield against chemical aggressors. The following are the important points explaining why fluoropolymers are so chemically inert:

High Electronegativity of Fluorine: Unlike conventional polymers that are hydrocarbons, consisting of chains of carbon and hydrogen atoms, in fluoropolymers, this chain is composed of fluorine and carbon atoms. The covalent bond between fluorine and carbon is one of the strongest bonds in organic chemistry. This is due to the high electronegativity of fluorine, which pulls electrons from carbon towards itself. Then, these electrons remain attracted to fluorine. When a chemical substance tries to react with the fluoropolymer through its electrons, nothing happens because these electrons will remain very attracted to fluorine. The chemical reaction will only occur with very potent reagents or very extreme environmental conditions.

Steric Barrier and Hindrance: Another reason why chemical reactivity is reduced in these coatings is because fluorine atoms are large in size and surround the carbon atoms, forming a sort of protective shield. It is difficult for reactive substances to penetrate through fluorine and reach the carbon.

From the imposing structures of modern architecture to the intricate machinery of medical devices, fluoropolymer coatings find their way into a myriad of applications:

Applications

Architecture: Fluoropolymer coatings adorn architectural masterpieces, offering both aesthetic appeal and functional resilience. From ETFE roofing materials to PTFE-bearing pads, they redefine the boundaries of design and durability.

Energy and Chemical Industries: Fluoropolymers play a vital role in safeguarding critical infrastructure. From pipes and ducts to data cables and filtration systems, they strengthen the foundations of public utility and chemical manufacturing, minimizing emissions and corrosion risks.

Renewable Energy: Fluoropolymer coatings empower renewable energy technologies with their unparalleled durability and resistance. Whether in bearings or protective films for photovoltaic cells, they pave the way for enhanced performance and longevity.

Medical Innovations: Fluoropolymers contribute to the development of life-saving medical devices and equipment. From catheters to sterile filters, they uphold the highest standards of safety and reliability, ensuring optimal outcomes for patients.

Aerospace and Automotive: Fluoropolymer coatings redefine the limits of performance and efficiency in aerospace and automotive industries. From electric wire insulation to fuel line protection, they safeguard critical components against wear, corrosion, and friction, enhancing both safety and longevity.

Achieving optimal performance begins with meticulous application techniques. Whether through compressed air sprays or electrostatic spray systems, the key lies in precise surface preparation and controlled curing processes. By adhering to stringent standards, manufacturers ensure the seamless integration of fluoropolymer coatings into diverse substrates, maximizing their effectiveness and longevity.

In today's industrial landscape, the demand for coatings that can withstand the toughest conditions while maintaining optimal performance has never been higher. Among the numerous options available, fluoropolymer coatings stand out as beacons of innovation and reliability. With a plethora of desirable properties, they have become indispensable in various industries, from aerospace to medical applications.

At the heart of fluoropolymer coatings lies a sophisticated molecular architecture, combining the robustness of the carbon skeleton with the resilience of fluorine bonds. But what sets them apart? These coatings exhibit a notable variety of characteristics:

Weather Resistance and Corrosion Protection: Fluoropolymer coatings offer a solid defense against corrosion and degradation, ensuring longevity even in the harshest environments.

Chemical Inertness: Fluoropolymers remain steadfast, maintaining their integrity in the face of chemical adversity.

Flame Retardancy: In the realm of safety, fluoropolymer coatings take center stage, offering inherently flame-retardant properties that enhance protection against fire hazards.

Nonstick and Low Friction: These coatings reduce friction and adhesion, promoting a finish that stains less and reducing maintenance costs.

High Dielectric Constant: Fluoropolymers exhibit a high dielectric constant, ensuring reliable insulation even under demanding conditions.

Chemistry

The secret of the exceptional properties of fluoropolymers lies in their atomic structure. Carbon and fluorine atoms, bound by covalent bonds, form a formidable shield against chemical aggressors. The following are the important points explaining why fluoropolymers are so chemically inert:

High

Electronegativity of Fluorine:

Unlike conventional polymers that are hydrocarbons, consisting of chains of carbon and hydrogen atoms, in fluoropolymers, this chain is composed of fluorine and carbon atoms. The covalent bond between fluorine and carbon is one of the strongest bonds in organic chemistry. This is due to the high electronegativity of fluorine, which pulls electrons from carbon towards itself. Then, these electrons remain attracted to fluorine. When a chemical substance tries to react with the fluoropolymer through its electrons, nothing happens because these electrons will remain very attracted to fluorine. The chemical reaction will only occur with very potent reagents or very extreme environmental conditions.

Steric Barrier and Hindrance:

Another reason why chemical reactivity is reduced in these coatings is because fluorine atoms are large in size and surround the carbon atoms, forming a sort of protective shield. It is difficult for reactive substances to penetrate through fluorine and reach the carbon.

Applications

From the imposing structures of modern architecture to the intricate machinery of medical devices, fluoropolymer coatings find their way into a myriad of applications:

Architecture: Fluoropolymer coatings adorn architectural masterpieces, offering both aesthetic appeal and functional resilience. From ETFE roofing materials to PTFE-bearing pads, they redefine the boundaries of design and durability.

Energy and Chemical Industries: Fluoropolymers play a vital role in safeguarding critical infrastructure. From pipes and ducts to data cables and filtration systems, they strengthen the foundations of public utility and chemical manufacturing, minimizing emissions and corrosion risks.

Renewable Energy: Fluoropolymer coatings empower renewable energy technologies with their unparalleled durability and resistance. Whether in bearings or protective films for photovoltaic cells, they pave the way for enhanced performance and longevity.

Medical Innovations: Fluoropolymers contribute to the development of life-saving medical devices and equipment. From catheters to sterile filters, they uphold the highest standards of safety and reliability, ensuring optimal outcomes for patients.

Aerospace and Automotive: Fluoropolymer coatings redefine the limits of performance and efficiency in aerospace and automotive industries. From electric wire insulation to fuel line protection, they safeguard critical components against wear, corrosion, and friction, enhancing both safety and longevity.

Achieving optimal performance begins with meticulous application techniques. Whether through compressed air sprays or electrostatic spray systems, the key lies in precise surface preparation and controlled curing processes. By adhering to stringent standards, manufacturers ensure the seamless integration of fluoropolymer coatings into diverse substrates, maximizing their effectiveness and longevity.

In today's industrial landscape, the demand for coatings that can withstand the toughest conditions while maintaining optimal performance has never been higher. Among the numerous options available, fluoropolymer coatings stand out as beacons of innovation and reliability. With a plethora of desirable properties, they have become indispensable in various industries, from aerospace to medical applications.

At the heart of fluoropolymer coatings lies a sophisticated molecular architecture, combining the robustness of the carbon skeleton with the resilience of fluorine bonds. But what sets them apart? These coatings exhibit a notable variety of characteristics:

Weather Resistance and Corrosion Protection: Fluoropolymer coatings offer a solid defense against corrosion and degradation, ensuring longevity even in the harshest environments.

Chemical Inertness: Fluoropolymers remain steadfast, maintaining their integrity in the face of chemical adversity.

Flame Retardancy: In the realm of safety, fluoropolymer coatings take center stage, offering inherently flame-retardant properties that enhance protection against fire hazards.

Nonstick and Low Friction: These coatings reduce friction and adhesion, promoting a finish that stains less and reducing maintenance costs.

High Dielectric Constant: Fluoropolymers exhibit a high dielectric constant, ensuring reliable insulation even under demanding conditions.

Chemistry

The secret of the exceptional properties of fluoropolymers lies in their atomic structure. Carbon and fluorine atoms, bound by covalent bonds, form a formidable shield against chemical aggressors. The following are the important points explaining why fluoropolymers are so chemically inert:

High Electronegativity of Fluorine: Unlike conventional polymers that are hydrocarbons, consisting of chains of carbon and hydrogen atoms, in fluoropolymers, this chain is composed of fluorine and carbon atoms. The covalent bond between fluorine and carbon is one of the strongest bonds in organic chemistry. This is due to the high electronegativity of fluorine, which pulls electrons from carbon towards itself. Then, these electrons remain attracted to fluorine. When a chemical substance tries to react with the fluoropolymer through its electrons, nothing happens because these electrons will remain very attracted to fluorine. The chemical reaction will only occur with very potent reagents or very extreme environmental conditions.

Steric Barrier and Hindrance:

Another reason why chemical reactivity is reduced in these coatings is because fluorine atoms are large in size and surround the carbon atoms, forming a sort of protective shield. It is difficult for reactive substances to penetrate through fluorine and reach the carbon.

Applications

From the imposing structures of modern architecture to the intricate machinery of medical devices, fluoropolymer coatings find their way into a myriad of applications:

Architecture: Fluoropolymer coatings adorn architectural masterpieces, offering both aesthetic appeal and functional resilience. From ETFE roofing materials to PTFE-bearing pads, they redefine the boundaries of design and durability.

Energy and Chemical Industries: Fluoropolymers play a vital role in safeguarding critical infrastructure. From pipes and ducts to data cables and filtration systems, they strengthen the foundations of public utility and chemical manufacturing, minimizing emissions and corrosion risks.

Renewable Energy: Fluoropolymer coatings empower renewable energy technologies with their unparalleled durability and resistance. Whether in bearings or protective films for photovoltaic cells, they pave the way for enhanced performance and longevity.

Medical Innovations: Fluoropolymers contribute to the development of life-saving medical devices and equipment. From catheters to sterile filters, they uphold the highest standards of safety and reliability, ensuring optimal outcomes for patients.

Aerospace and Automotive: Fluoropolymer coatings redefine the limits of performance and efficiency in aerospace and automotive industries. From electric wire insulation to fuel line protection, they safeguard critical components against wear, corrosion, and friction, enhancing both safety and longevity.

Achieving optimal performance begins with meticulous application techniques. Whether through compressed air sprays or electrostatic spray systems, the key lies in precise surface preparation and controlled curing processes. By adhering to stringent standards, manufacturers ensure the seamless integration of fluoropolymer coatings into diverse substrates, maximizing their effectiveness and longevity.