The coatings industry has grown and evolved considerably over time, much like many other industries. The introduction of advanced technologies, new techniques, innovative materials, and specialized skills has significantly expanded the applications of various paints and coatings, allowing them to adapt to the changing demands of consumers. One material that has revolutionized the way we formulate coatings is graphene.

The history of graphene and its understanding dates back to 1947, when physicists began to theorize about how a two-dimensional carbon structure would look and function. However, it was in 2004 when Andre Geim and Konstantin Novoselov managed to isolate graphene using a simple yet innovative technique known as the "Scotch tape method" or mechanical exfoliation. They used adhesive tape to peel layers of graphite until obtaining a single layer of carbon atoms, graphene. Their work was published in the journal Science and was revolutionary because it demonstrated the unique properties of graphene, such as its high electrical and thermal conductivity, transparency, and incredible strength. Since then, scientists in the coatings industry have developed methods to use graphene as an additive to enhance the performance of various coating technologies. This material has become particularly essential in modern high-performance, high-demand industries where coatings are required to consistently deliver exceptional performance in challenging and aggressive environments.

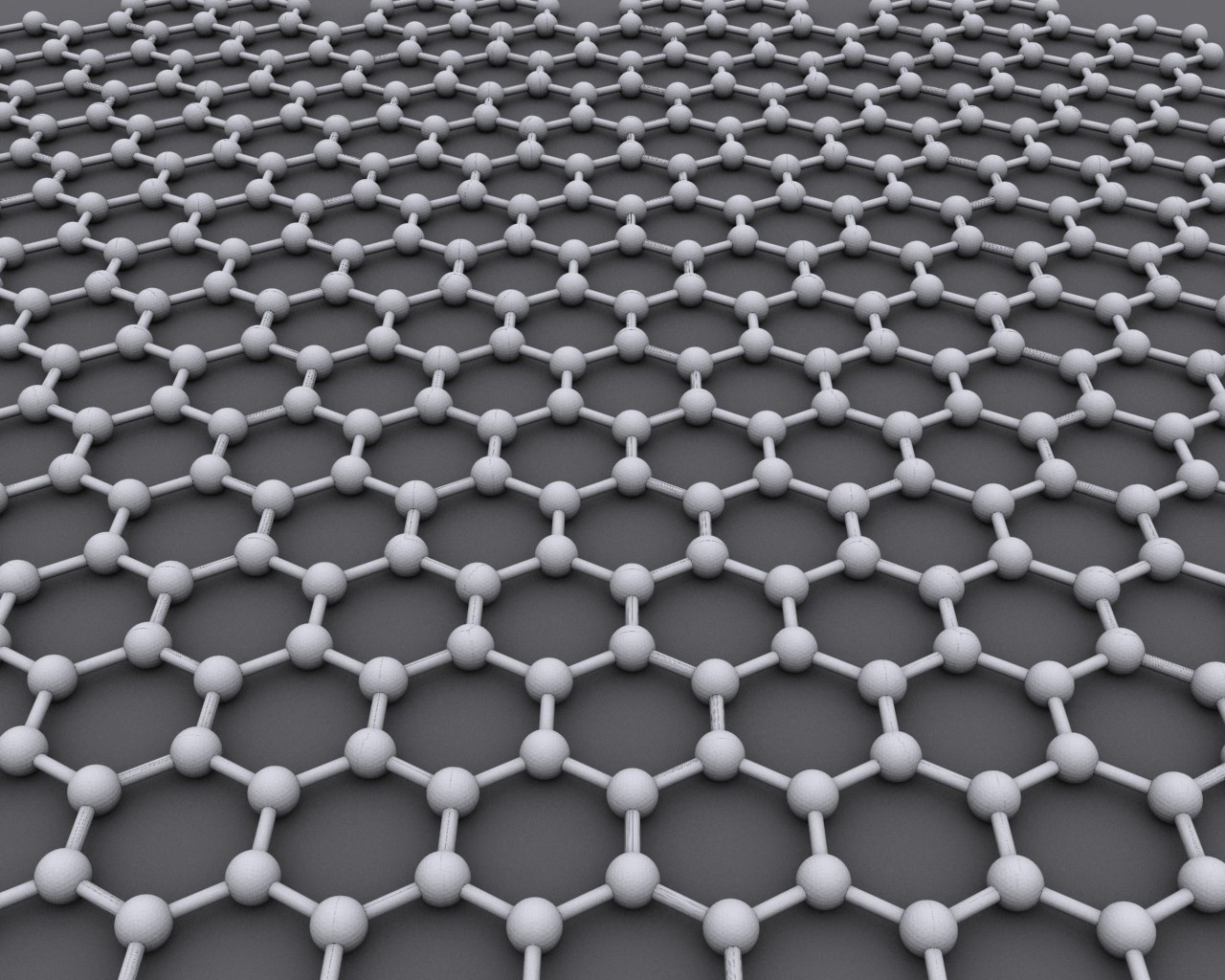

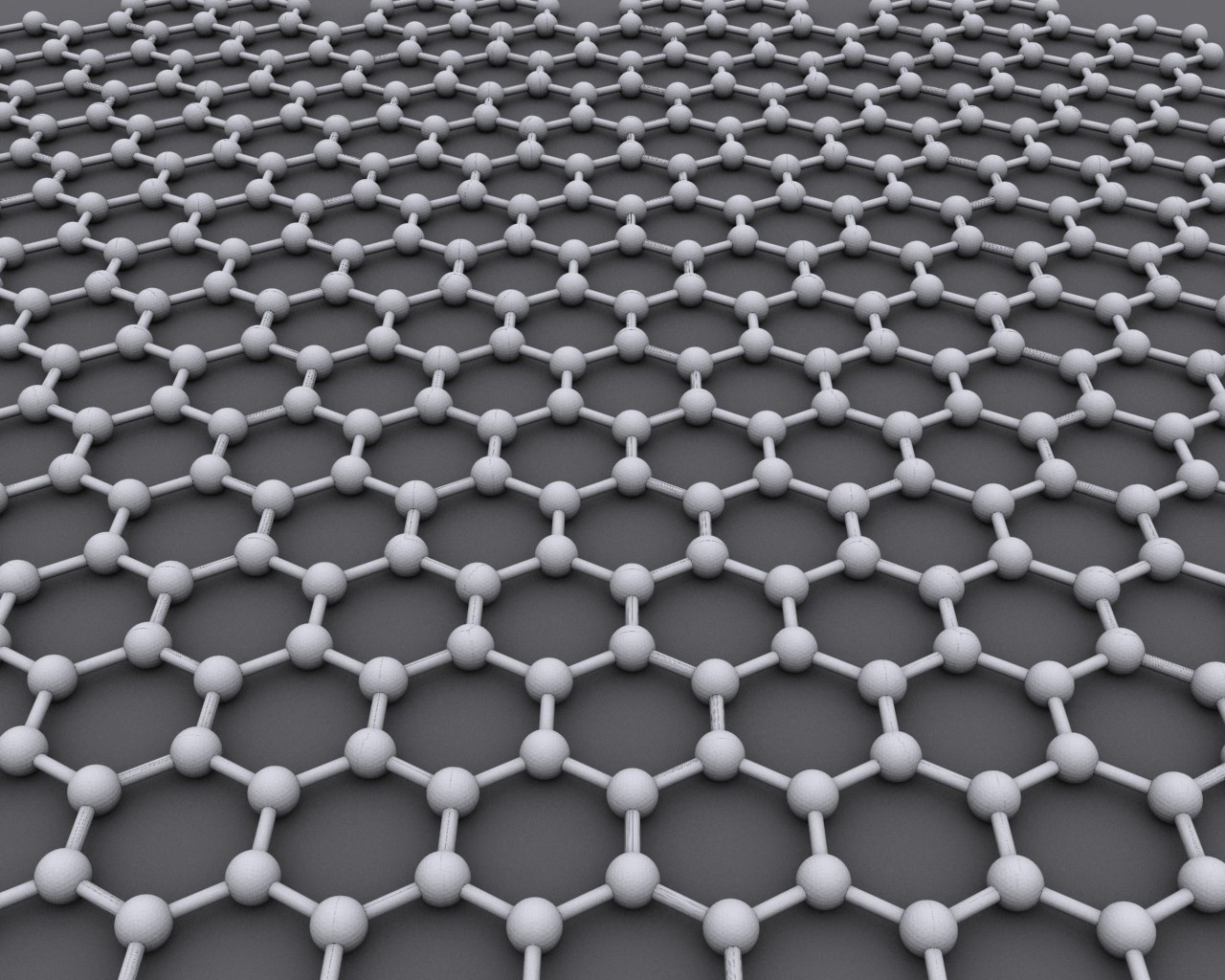

What is Graphene

Graphene is a two-dimensional material composed of a single layer of carbon atoms arranged in a hexagonal structure similar to a honeycomb. Being two-dimensional makes it a particularly large molecule, but extremely thin: only one atom thick. It is the thinnest material known to man.

Properties of Graphene

The carbon atoms in graphene are organized in a hexagonal pattern in a single layer. Each carbon atom is strongly bonded to three neighboring carbon atoms through covalent bonds, creating a flat network structure. The covalent bonds in graphene are extremely strong, giving it high mechanical strength. Graphene is one of the strongest known materials, being about 200 times stronger than steel, yet it is also very flexible and elastic. It is extremely light, with a very low weight due to its two-dimensional structure.

Graphene is an excellent conductor of electricity due to the extremely high mobility of its electrons. This is because of the delocalized pi electrons that can move freely through the two-dimensional structure. It is also an excellent conductor of heat, with thermal conductivity superior to most materials.

Graphene is nearly completely transparent, absorbing only 2-3% of light, making it ideal for applications in displays and optoelectronic devices.

How is Graphene Used in Coatings?

First, graphene acts as a structural reinforcement within the polymer matrix of the paint. Due to its strong covalent bonds and high tensile strength, graphene reinforces the polymer matrix, improving the mechanical strength and durability of the coating. This not only increases the wear and abrasion resistance of the coating but can also prolong the life of the protected substrate.

In addition to its improved mechanical properties, graphene provides an effective barrier against corrosion. The two-dimensional structure of graphene forms an impermeable layer over the surface of the substrate, preventing the penetration of moisture, oxygen, and other corrosive agents. This barrier capability helps prevent corrosion by keeping the underlying materials from coming into contact with corrosive environments, such as marine or industrial settings.

Another key advantage of graphene in coating paints is its excellent electrical and thermal conductivity. This property is particularly useful in applications where heat dissipation or protection against static charge buildup is required. Additionally, graphene can enhance the conductivity of conductive coatings used in applications such as sensors, electronic devices, and anti-static coatings.

Uses of Graphene Coatings

Graphene, with its exceptional strength and negligible weight, is highly suitable for a variety of coating formulations used in industries where durability, lightweight, and water resistance are paramount. These applications include surfaces like ship hulls, pressure vessels, cookware coatings, and glass surfaces. Additionally, substrates that require protection against aggressive chemicals, fire, moisture, corrosion, and UV degradation can significantly benefit from the properties of graphene coatings. Industrial sectors exposed to hostile environments, such as aerospace, electrical, alternative energy, and specialized chemicals, can find valuable applications in this technology.

The advantages of using graphene coating formulations include superior adhesion to substrates, excellent repaintability, reduced maintenance costs, extended maintenance intervals, and enhanced anti-corrosion performance under aggressive environmental conditions.

Copyright ©️ 2024, COSMOS Coatings.

Copyright ©️ 2024, COSMOS Coatings.