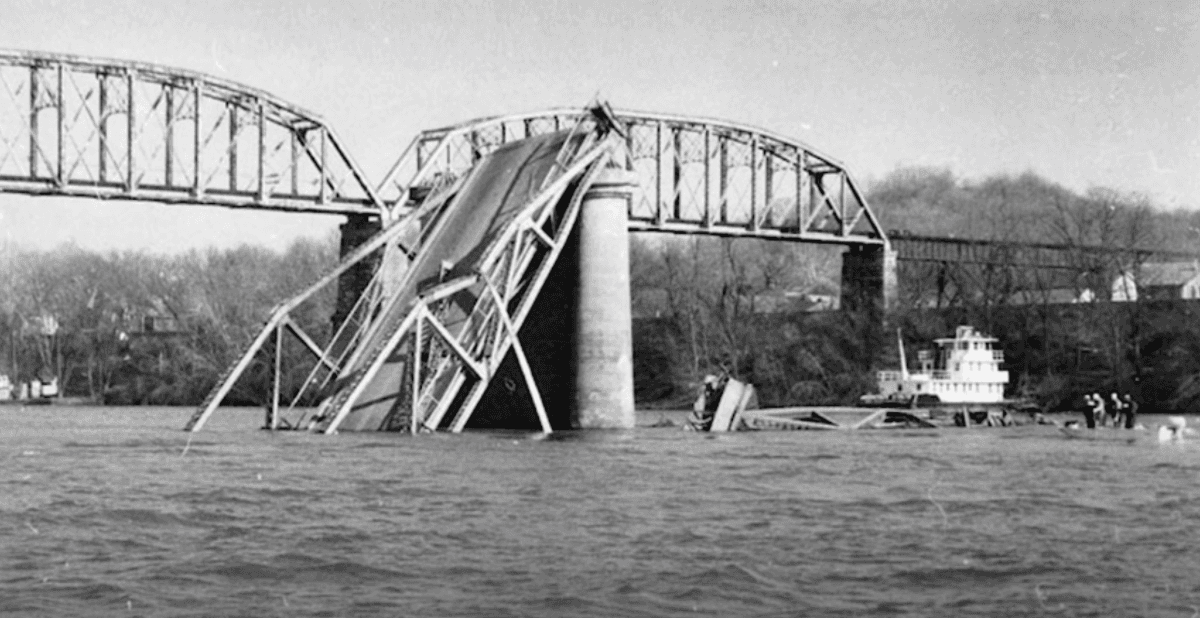

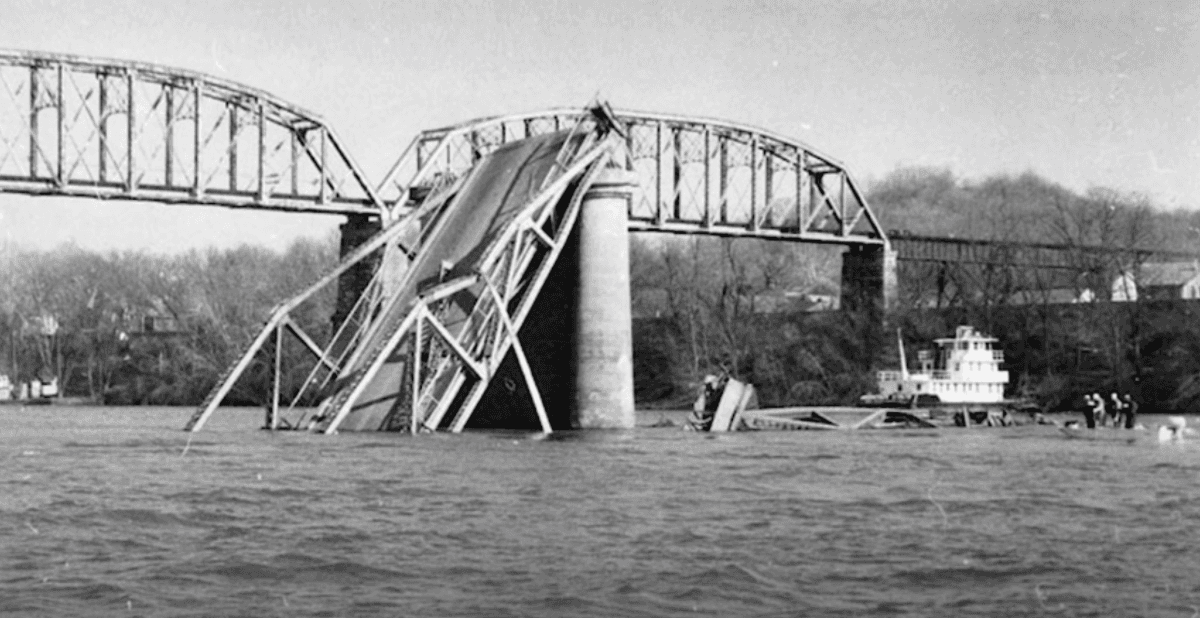

The Silver Bridge collapse, a tragic event that occurred on December 15, 1967, stands as one of the most significant engineering failures in the United States. The collapse of the Silver Bridge, spanning the Ohio River between Point Pleasant, West Virginia, and Gallipolis, Ohio, resulted in the loss of 46 lives and highlighted critical shortcomings in bridge maintenance and structural integrity.

While various factors contributed to the disaster, including design flaws and overloading, the role of protective coatings in preventing corrosion and structural deterioration cannot be overlooked.The Silver Bridge, constructed in 1928, was a vital transportation link connecting communities on both sides of the Ohio River. The collapse occurred during rush hour traffic, with the bridge suddenly giving way under the weight of vehicles and pedestrians, plunging them into the icy waters below. Investigations revealed that the failure originated from a single eyebar, which fractured due to stress corrosion cracking, ultimately leading to the catastrophic collapse.

The Importance of Coatings in Bridge Maintenance

Coatings play a crucial role in protecting bridge structures from corrosion, a leading cause of deterioration in steel components exposed to harsh environmental conditions. Bridges, especially those spanning rivers or coastal areas, are susceptible to corrosion due to exposure to moisture, salt spray, and atmospheric pollutants. Protective coatings act as a barrier, shielding steel surfaces from corrosive agents and extending the service life of bridge structures.

Preventative Measures with Coatings

Corrosion protection

The application of high-performance coatings with corrosion-resistant properties could have prevented the deterioration of critical components, including the eyebar that failed in the Silver Bridge collapse. Coatings designed to withstand exposure to moisture and corrosive elements would have provided long-term protection against corrosion, reducing the risk of structural failure.

Regular inspection and mantainance

Implementation of routine inspection and maintenance programs is essential for detecting signs of corrosion or coating degradation early on. Regular cleaning, surface preparation, and recoating can help maintain the integrity of protective coatings and identify potential structural weaknesses before they escalate into catastrophic failures.

Advance coating tecnologies

Advancements in coating formulations, such as epoxy and zinc-rich primers, offer superior corrosion protection and adhesion properties, ideal for bridge applications. These advanced coatings provide enhanced durability and resistance to environmental factors, minimizing the need for frequent maintenance and reducing life cycle costs.

Compiliance with standards and specifications

Adherence to industry standards and specifications for coating selection, application, and maintenance is critical for ensuring the effectiveness of protective systems. Compliance with established guidelines, such as those set forth by the American Association of State Highway and Transportation Officials (AASHTO), can help bridge owners and operators mitigate corrosion-related risks and enhance safety.